Asset monitoring and management

designed for the manufacturing industry

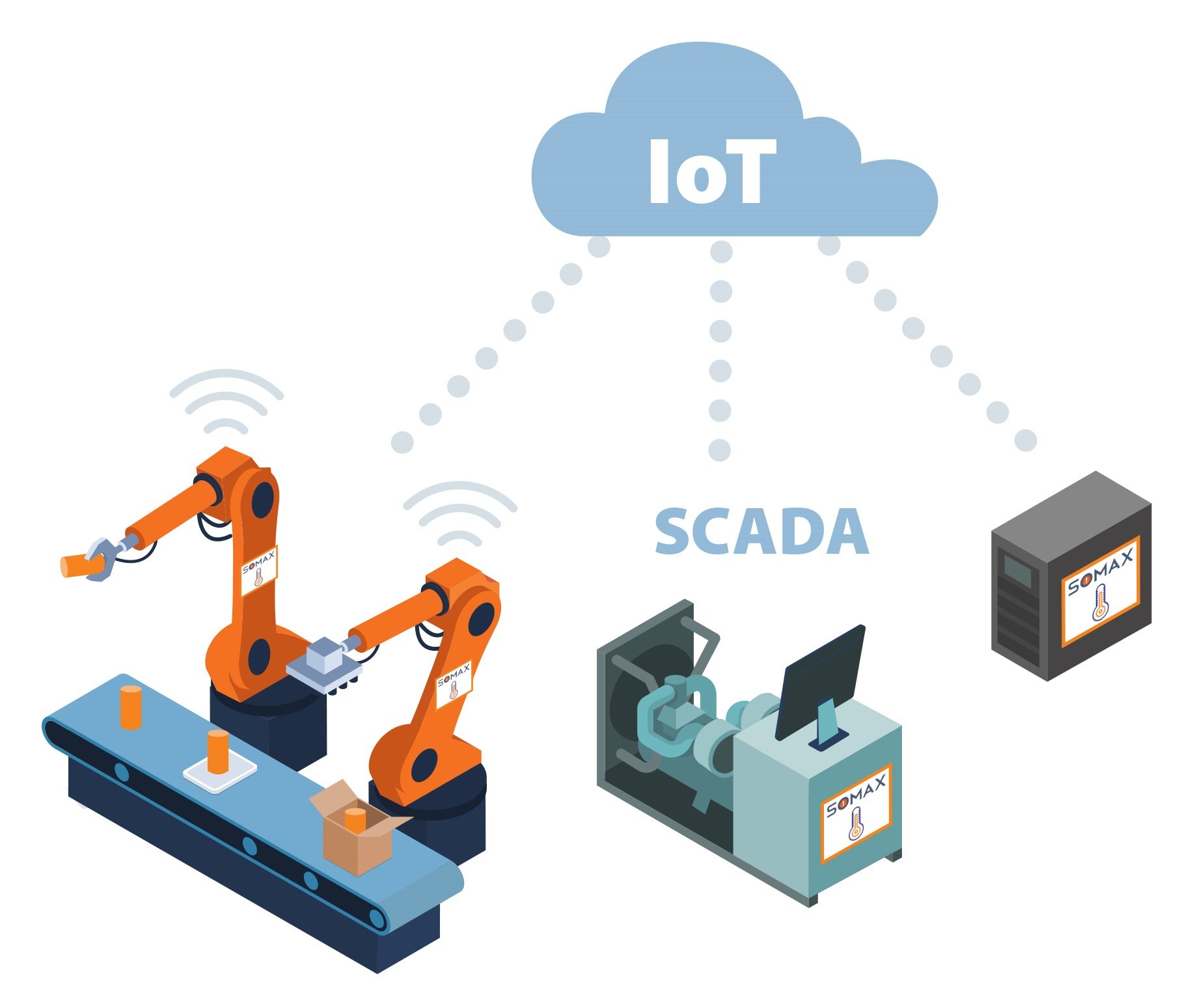

Integrate SOMAX with equipment sensors to create a truly predictive maintenance program. Use high-low thresholds for gauges or cycle count limits for meters to automatically create work requests and orders. Leverage our Internet of Things integration for real-time, system generated alerts and notifications.

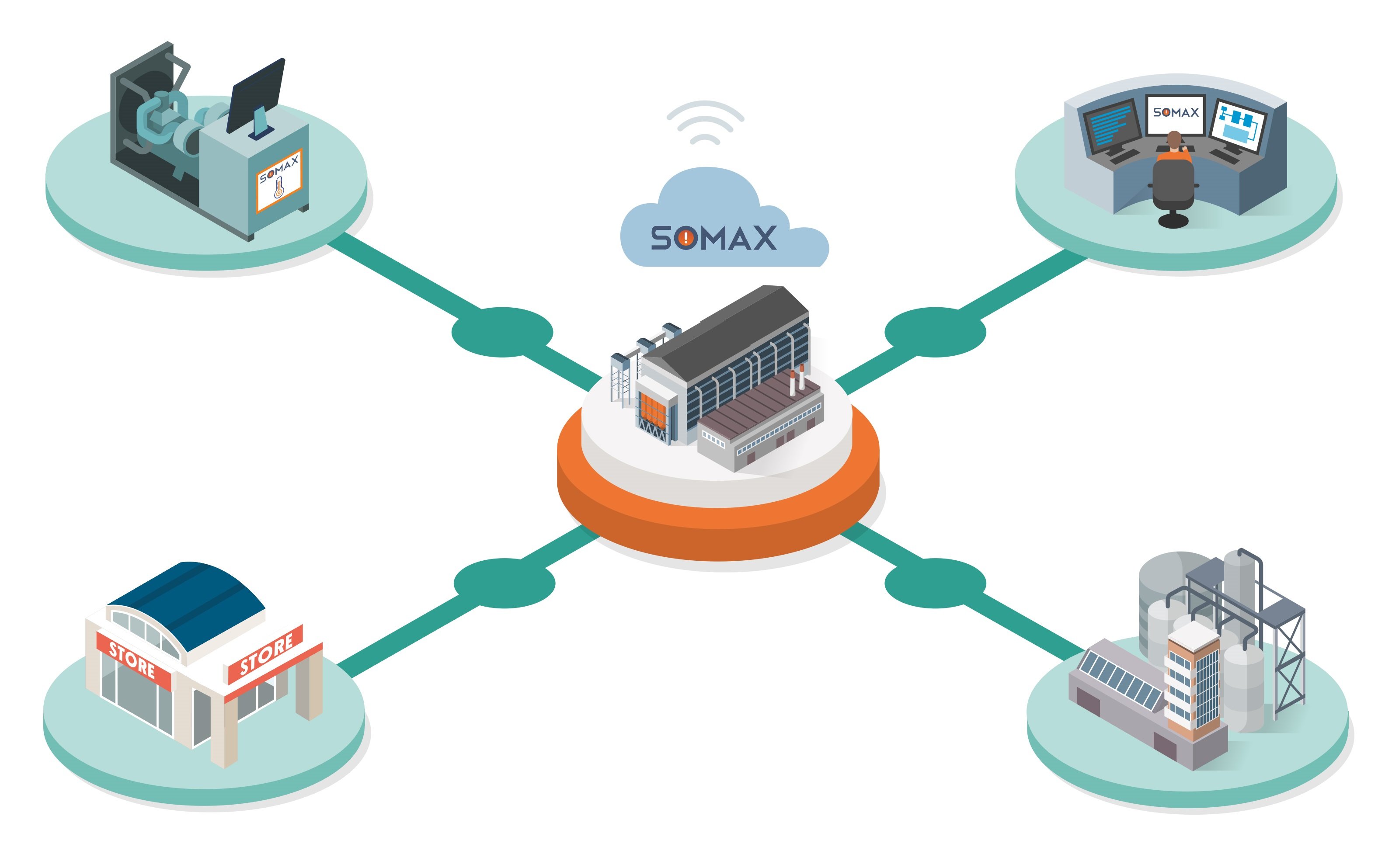

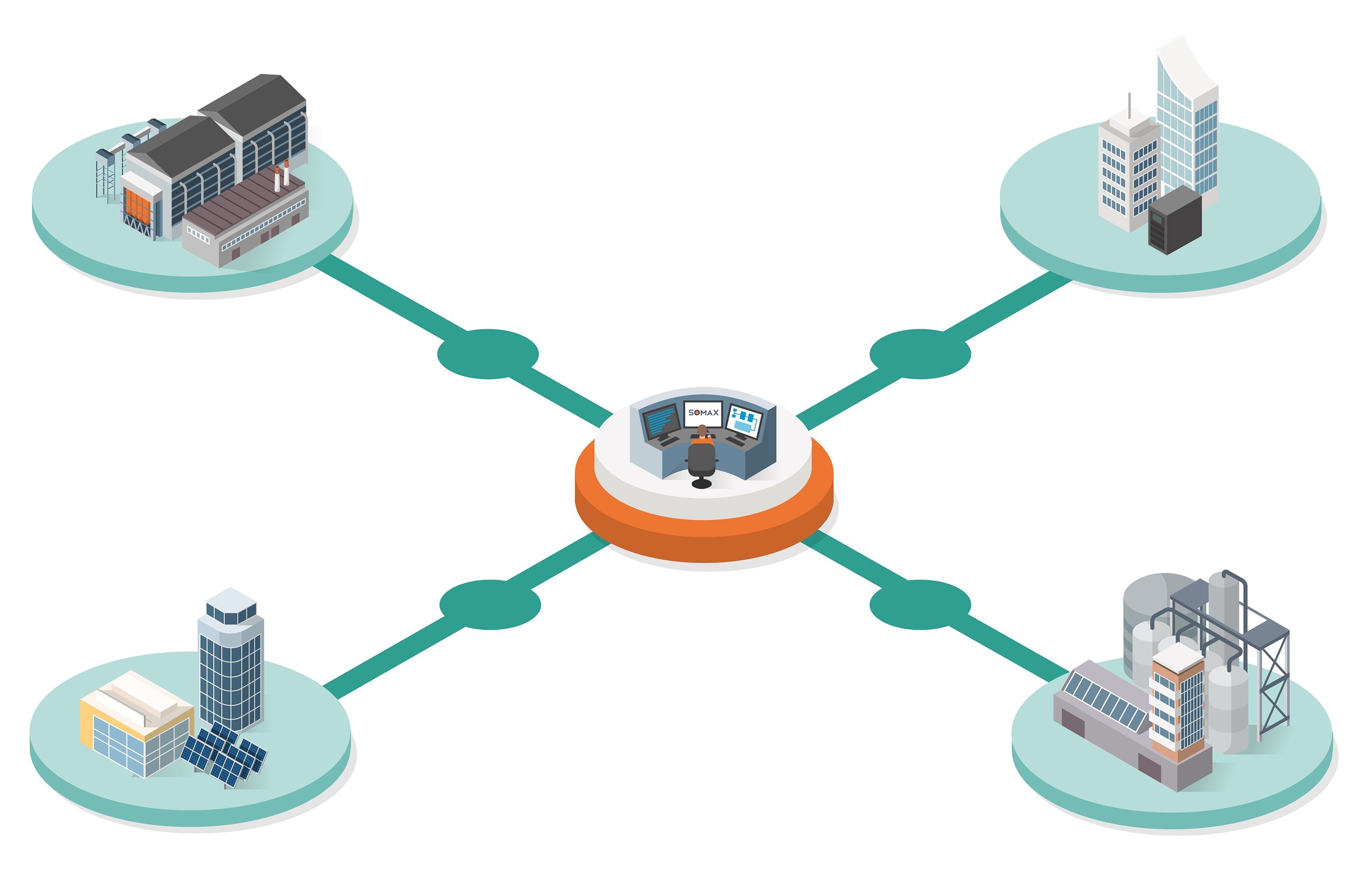

Multi-site, multi-location system easily scales to any size organization no matter how many facilities. Search for and gather information on assets, parts and work across all the sites in your organization. From one site to thousands, SOMAX CMMS can handle it.

Track and eliminate costly breakdowns. Collect information about downtime reasons, time down, work performed and notes about downtime, all within either our web or mobile app.

Take advantage of bar-coding simplicity and scan bar-coded equipment in the plant straight from your smartphone or tablet. Full equipment history can be pulled from bar-code scan. Check out parts to work orders using phone or tablet bar-code scanner for ease and mobility.

SOMAX includes a full inventory tracking and procurement system. Vendor control for streamlined purchasing, project management, and contract labor. Ensure your parts room is always stocked, and track part usage in our web or mobile app.

Always stay connected to the plant floor through:

Stay connected to key vendors and other support systems vital to your plant’s operation with:

Verify and validate maintenance performed with:

Ensure everything is maintained to the same standard by creating and enforcing standards across your all of your sites, including:

We basically documented everything, so you can easily build new templates and sections.

Get the best answers possible directly from the developers of the theme within 24 hours (or faster).